|

Inlet wire diameter |

Φ8.0mm |

|

Outlet wire diameter |

Φ1.35~3.5mm |

|

Max. Line speed |

25 m/s (Max.) |

|

Drawing capstan diameter |

Φ450mm |

|

Drawing pass |

13 draft (Max.) |

|

Length of accumulated wire |

>7m |

|

Size of take-up bobbin |

PND630 PND500 |

|

Speed reduction ratio between capstans |

1.278(2~11)、1.25(12)、13

(Die No. 13 is adjustable)

|

|

Motor of main drawing machine |

250KW/ DC , Z4-315-12, 1000rpm |

|

Motor of final capstan |

75KW / DC , Z4-200-21 |

|

Motor of dual spooler |

30KW/ AC * 2 pcs |

|

Die holder size |

Φ53x35 mm |

|

Annealing current |

Max. 4300A |

|

Annealing voltage |

Max.55V/AC |

|

Total install power |

838KVA |

|

Power supply |

380V/50hz |

|

Operation direction |

Operator face to machine: left is P/O, right is T/U |

|

Machine color |

Standard RAL5015 or To be confirmed by buyer |

|

1 |

Pay-off stand with a rotating single arm |

1 set |

|

2 |

Wire Pointing & Threading Device |

1 set |

|

3 |

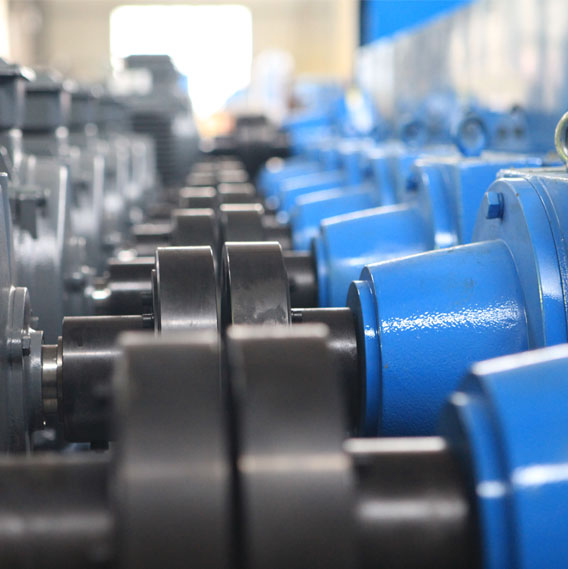

Main wire drawing machine (casting gearbox of main machine) |

1 set |

|

4 |

Lubricating system and cooling system for main gear box and drawing oil tank |

1 set |

|

5 |

Annealer |

1 set |

|

6 |

Vertical wire tension accumulator |

1 set |

|

7 |

Pneumatic Dual spooler(Ф500mm, Ф630mm) |

1 set |

|

8 |

Use NSK bearing for all of main machine device, besides ones from out purchased goods, such as pump, motor, etc. |

1 set |

|

9 |

Electrical control system |

1 set |